What is a masonry stabiliser?

A masonry stabiliser is a chemical solution applied to masonry surfaces to reinforce and protect them. It penetrates the material, binds loose particles, and provides long-lasting stability.

When should I use a masonry stabiliser?

Masonry stabiliser is used on buildings with crumbling or deteriorating stone, brick, or mortar. They can also be applied to new constructions to prevent future degradation, particularly in areas exposed to harsh weather conditions.

How do masonry stabilisers work?

These stabilisers work by penetrating deep into the masonry surface, where they chemically react with the material to form a strong, water-resistant bond. This process helps to consolidate the masonry, preventing further deterioration and strengthening the structure.

What are the benefits of using a masonry stabiliser?

- Enhanced durability: Provides long-term protection against weathering and physical damage.

- Water resistance: Helps prevent water penetration and related issues like efflorescence and mold.

- Preservation: Maintains the appearance and structural integrity of historic buildings.

- Improved surface stability: Binds loose particles, reducing dust and debris.

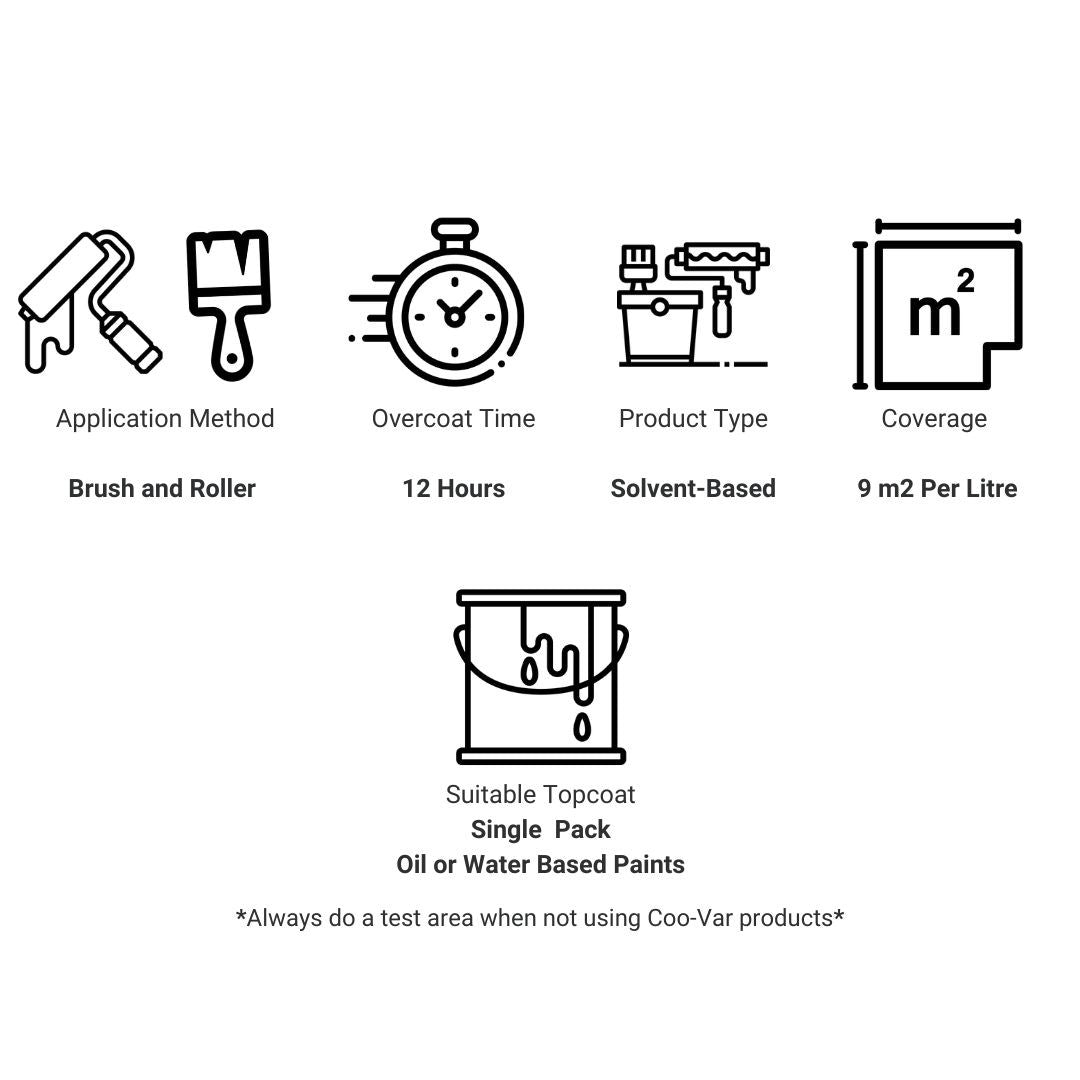

How is a masonry stabiliser applied?

The application process generally involves:

- Cleaning the surface: Removing dirt, debris, and any loose material.

- Applying the stabiliser: Using a brush or roller to apply the product evenly.

- Allowing time to cure: Letting the stabiliser penetrate and cure, which can take 5-7 days, depending on the temperature.

Can masonry stabilisers be used on all types of masonry?

Masonry stabiliser is suitable for many types of masonry, including brick, stone, and mortar.

How long does the effect of a masonry stabiliser last?

The longevity of the stabiliser's effect can vary depending on the product, application method, and environmental conditions. Generally masonry stabiliser can provide protection for several years.

Are masonry stabilisers safe to use?

Masonry stabilisers is safe when used according to the manufacturer's instructions. It's essential to wear appropriate protective gear, such as gloves and goggles, during application. Ensure proper ventilation if applying indoors.